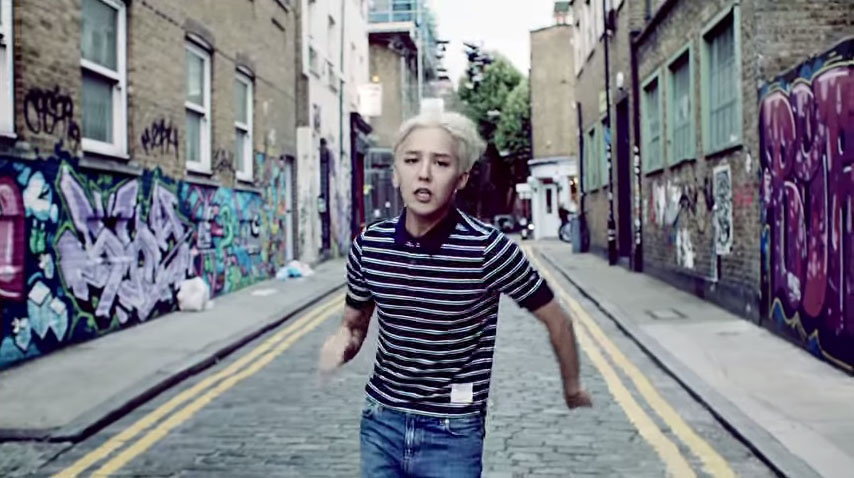

handheld laser marker

Some inkjet printers use water-based ink, which is only suitable for printing on permeable materials, not suitable for printing on non-permeable materials. For example, it is suitable for printing on paper and wood, but not suitable for printing on plastics and metals.

CYCJET CH3

Through proofing, we can choose the appropriate type. The small character inkjet printer is to print ink on the surface of the product. The equipment purchase cost is relatively low, but the original ink needs to be purchased, and the printed content can be erased with chemicals.

Large Character Inkjet Printers

CYCJET CO2 lasers have an IP65 (dust and water resistance) rating, which means they work well in harsh environments such as dairy and beverage production. They also provide excellent human-machine readable codes on high-speed production lines. They are ideal solutions for the dairy, medical, beverage, food, pharmaceutical, health and beauty and tobacco industries.

Automatic Coding & Marking

such as food, beverage, building materials, chemicals, electronics,medicine, daily cosmetics, packaging, etc.

Continuous Inkjet Printers(CIJ)

Pharmaceutical and health care products industry: Print information such as drug name, specifications, production date, expiration date, etc. on the packaging of drugs and health care products to ensure the safety of consumers' medication.

Labelling Machines

Piezoelectric inkjet technology: Piezoelectric inkjet printer is also called high resolution inkjet printer or high resolution inkjet printer. On the integrated nozzle, 128 or more piezoelectric crystals are used to control the nozzle. The plurality of nozzle holes on the board are processed by the CPU, and then a series of electrical signals are outputted to the respective piezoelectric crystals through the driving board, and the piezoelectric crystal is deformed, so that the ink is ejected from the nozzle and falls on the surface of the moving object. , forming a dot matrix to form words, numbers or graphics. Then, the piezoelectric crystal is restored to its original state, and new ink enters the nozzle due to the surface tension of the ink. Because of the high density of dots per square centimeter, piezoelectric technology can be used to print high-quality text, complex logos, and barcodes.

CYCJET BW3020

Its body shell adopts innovative coating technology, which has high corrosion resistance, hardness, excellent heat insulation and heat resistance, and is suitable for various harsh working environments. Its minimalist appearance design, crafted with ingenuity and precision, integrates innovation and technology, and takes into account both interior and appearance. It is modern and simple, and interprets the ultimate aesthetics.

Why choose CYCJET?

Environmental protection and energy saving: The laser marking machine does not need to use chemical reagents during operation, reducing environmental pollution and energy consumption.

Lot Code Printers

In summary, UV inkjet printers, large character inkjet printers and high-resolution handjet printers have their own characteristics and complementary advantages in the identification of woven bags. They not only improve the accuracy and traceability of product information, but also promote the improvement of production efficiency and environmental benefits. With the continuous advancement of technology and the continuous changes in market demand, CYCJET inkjet printer equipment will continue to play an important role in the field of woven bag identification, providing more efficient and convenient solutions for modern industrial production and logistics management.

Date Code Printers

In the field of medical equipment, mini laser marking machines also play an important role. Doctors can use laser marking machines to mark the manufacturer, use period and other information on medical devices to facilitate tracking and management. At the same time, laser marking can also leave special marks on medical devices for easy identification and tracking, greatly improving the management efficiency of medical equipment.

portable label printer

Nowadays, with the rapid development of laser equipment and the improvement of the power of ultraviolet laser marking machines, ultraviolet laser marking machines have been used in the high-end market of ultra-fine processing. Medical and pharmaceuticals, medical devices, cosmetics, food, IC chips, electronic components, building materials, plastic keys, and many other fields and industries,

High Speed Fly Laser Printers

The application of handheld laser coding machines in food packaging has better guaranteed food safety. Some manufacturers use laser marking machines to mark production date, shelf life and other information on the packaging. This information can be clearly and permanently retained on the packaging, avoiding the blurring or falling off problems that may occur with handwriting or spray coding. At the same time, the laser marking machine will not corrode packaging materials, ensuring food safety.

portable coding system

In the wave of modern production, marking technology has become a key link for enterprises to achieve efficient management and quality control. As an efficient and accurate marking tool, inkjet printing machines are gradually favored by more and more companies. CYCJET focuses on the R&D and application of inkjet printer technology and is committed to providing enterprises with stable and reliable marking solutions.

CYCJET ALT300

The beginning of the school year is a peak season for school supplies. Parents are busy preparing various learning tools for their children, and merchants are racking their brains to attract consumers with more creative and attractive products. In such a competitive environment, the emergence of cycjet uv inkjet printers provides a brand news solution for the school supplies market. UV inkjet printers can not only process various school supplies quickly and efficiently, but also bring many unexpected advantages and values.

CYCJET ALT160Plus

As a leader in the field of laser marking processing for light and thin materials, CYCJET CO2 laser marking machines are widely used in industries such as food packaging bags, packaging films, and transparent plastic bottles. It can carry out fine engraving, while ensuring that the film with a thickness of only 0.01mm will not be pierced by the laser, and at the same time ensure the firmness of the style content.